PERLE (Powerful Energy Recovery Linac for Experiments) is a compact three-pass ERL project based on SRF technology, being a new generation machine targeting the 10 MW beam power regime. Apart from the experiments it could host thanks to its beam characteristics, PERLE will serve as a hub for the validation and exploration of a broad range of accelerator phenomena in an unexplored operational power regime serving for the development of ERL technology for future energy and intensity frontier machines. While the concept and promise of ERL has been kick-started by demonstration machines based on existing accelerator technology, PERLE is meant to be the first machine designed from the ground up to use fully optimized ERL-specific designs and hardware. To attend this goal, an international collaboration is formed around the project, involving today CERN, JLAB, STFC, University of Liverpool, Cornell University, An-Najah University, ESS-Bilbao and CNRS (IJCLab + LPSC) (collaboration with BINP-Novosibirsk being suspended). All collaborators are leading laboratories on accelerator physics with experience of ERL development and operation for some (JLab, STFC and Cornell University). IJCLab is leading the collaborative effort towards the realization of the project. Furthermore, PERLE will be the facility that offers the possibility to uniquely demonstrate and validate multi-turn ERL operation with a high beam power and beams of different energies in the same SRF system. This would pave the way to a new generation of compact but powerful ERLs for applications requiring high energy beam and/or high total current (e.g. photon generation by Compton back-scattering, high-energy cooling source for ions, electron-ions collider).

PERLE design and main beam parameters

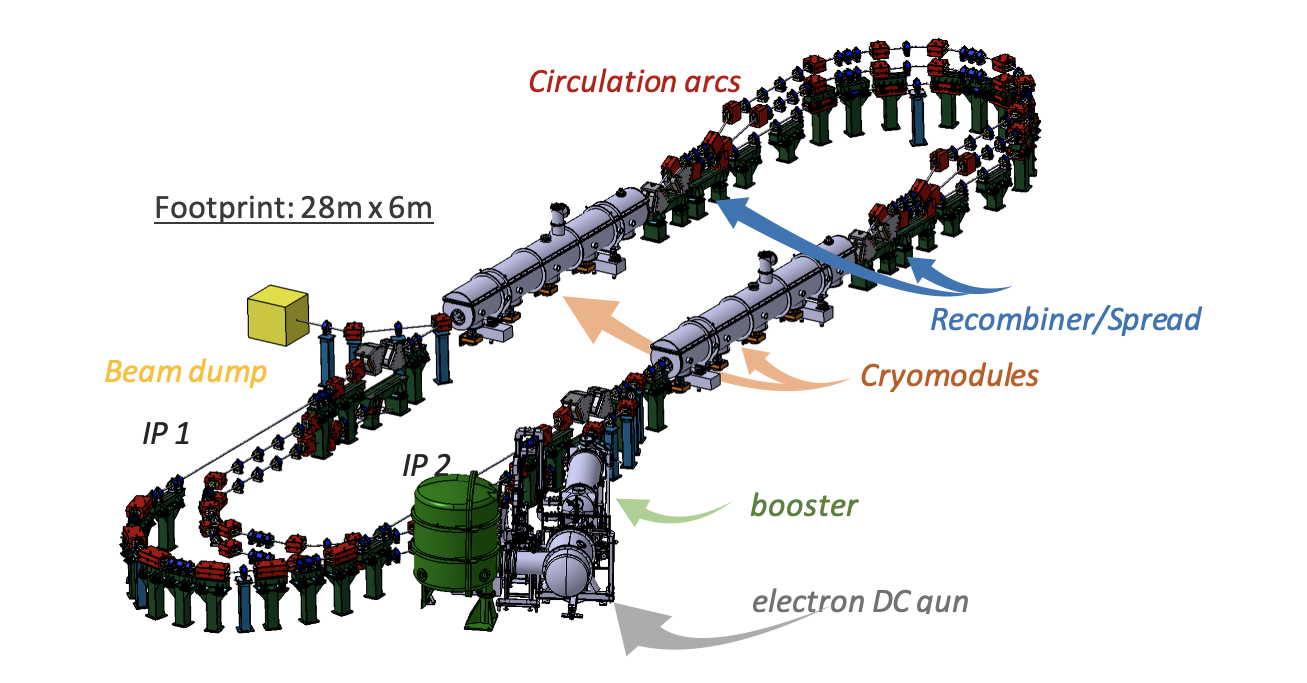

The PERLE accelerator complex (see figure) is arranged in a racetrack configuration hosting two cryomodules (containing four, 5-cell cavities operating at 801.6 MHz), each located in one of two parallel straights completed with a vertical stack of three recirculating arcs on each side. Additional space between the straights and the arcs is taken by long spreaders/recombiners, including matching sections. The spreaders are placed directly after each linac to separate beams of different energies and to route them to the corresponding arcs. The recombiners facilitate just the opposite: merging the beams of different energies into the same trajectory before entering the next linac. The path-length of each arc is chosen to be an integer number of RF wavelengths except for the highest energy pass, arc 6, whose length is longer by half of the RF wavelength to shift the RF phase from accelerating to decelerating, switching to the energy recovery mode. All six, 180° horizontal arcs are configured with Flexible Momentum Compaction (FMC) optics to ease individual adjustment of M56 in each arc (needed for the longitudinal phase-space reshaping, essential for operation with energy recovery).

PERLE Layout featuring two parallel Linacs each hosting a cryomodule housing four 5-cell SC cavities, achieving 500 MeV in three passes.

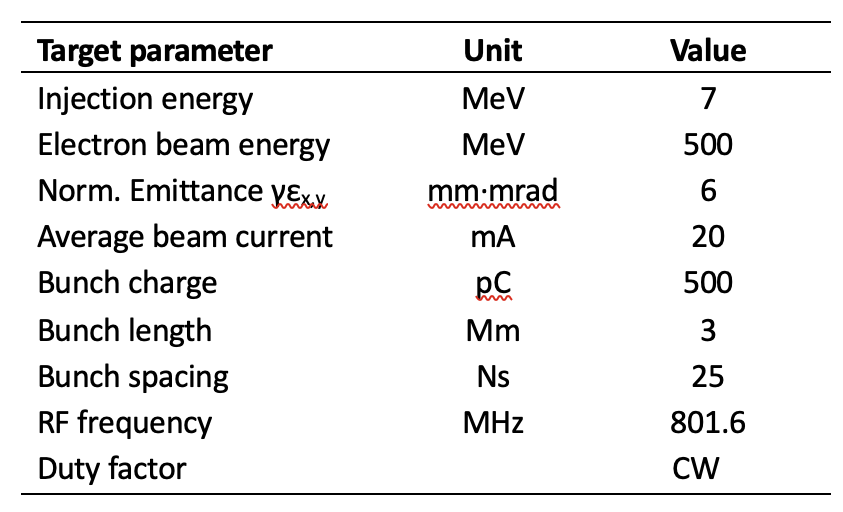

Each of the two cryomodules provides up to 82 MeV energy boost to the high average current electron beam (20mA). Therefore, in three turns, a 492 MeV energy increase is achieved. Adding the initial injection energy of 7 MeV yields the total energy of approximately 500 MeV. The beam is then used for its intended purpose (e.g. photon generation by Compton back-scattering, a cooling source for ion beams or collision with ions). This process may increase the energy spread or the emittance of the electron beam, but the major part of the beam power remains. The beam is then again sent back through the accelerators, this time roughly 180 degrees off the accelerating RF phase to be decelerated through the same number of passes and its energy is deposited into cavities allowing the acceleration of newly injected bunches, thereby effectively cancelling the beam loading effects of the accelerated beam. The remaining beam is sent to a dump at around the injection energy. The main beam parameters of PERLE facility are summarized in the table below.

PERLE Beam Parameters

PERLE phasing strategy from design to full construction:

1. The Technical Design Phase (TDR) - 2020-2023:

The initial and crucial phase of the PERLE project that should lead to the publication of a Technical Design Report (TDR) by the end of 2023. The studies planned within this phase are:

- Consolidation of the PERLE design by performing optic lattice and beam dynamics studies of the injection line, the 250 MeV and the 500 MeV versions of the machine.

- Design of the main systems and components of the machine (Buncher, Magnets, HOM couplers, full dressed cavity, power couplers, new CM, IP, dump…)

- Studies of the adaptation and upgrade possibilities of the in-kind equipment foreseen (DC Gun, Cryomodule, booster)

- Definition of the needs on Diagnostics, Cryogenics, CC, LLRF, Shielding, machine interlock system, infrastructure…

- Identifying the possible experiments with the PERLE beam and their specific needs and impact on the footprint.

Further required studies and design efforts of some systems could of course continue beyond this phase. Test results of some prototypes, planned in the preparatory to build phase, could also be included in the TDR if available.

2. The Preparatory to Build Phase (P2B) - 2022-2025:

The current phase of the PERLE project is characterized by a number of important/essential additional and complementary objectives to the TDR that must be met before construction can begin. We call this phase Preparation to Build: P2B. The objectives are:

- The commissioning of the in-kind received instruments from the international partnerships: installation of the DC gun and its upgrade to PERLE performances.

- The realization of critical prototypes that are needed before the start of the construction. The choice for the time being is to concentrated on prototyping cavities for the main loop cryomodule and for the booster as well as HOM fundamental power couplers.

- The preliminary work on infrastructure.

- The work related to the administrative classification of PERLE (ASN authorisation).

A clear consequence is that the objectives and timing of the TDR will not need to be changed. The TDR could eventually include "P2B deliverables" at the time of publication which is foreseen at the end of 2023. This phase will run up to the beginning of the construction of the main systems (by 2025).

3. Construction phasing:

The PERLE configuration shown in the figure entails the possibility to construct PERLE in stages. We defined three main phases for the construction with their objectives and timelines:

- Phase 1: Installation of the injection line (2022-2027): With a beam dump at its end. The injection line includes the DC gun, the load lock photocathode system, solenoids, buncher, booster, merger and required beam instrumentations to qualify the generated beam. The commissioning of the injection line will require the installation of cryogenics, RF power source, power supplies for the optics, photocathode laser, beam dump, control-command, vacuum systems, site shielding, safety control system, fluids, etc. Many of these installations must be already sized according to the final configuration of PERLE.

- Phase 2: 250 MeV version of PERLE (2024-2028): Installation of a single linac in the first straight and installation of the beam pipe and the complete return arcs. The switchyards have to be chosen according to the beam energy at each end (energy acceptance ratio: 1:2:3 for the spreader and combiner). This version of the race track is connected to the injection line built in phase 1, via the merger. This intermediate step will allow in relatively short term and lower expense to test with beam the various SRF components, to prove the multi-turn ERL, high-current operation and to gain essential operation experience with ERL. This version of PERLE will be extensively studied in the TDR.

- Phase 3: 500 MeV version of PERLE (2028-2031): The realisation of PERLE at its design parameters, as a 10 MW machine. This will imply the production of a dedicated further cryomodule and switchyards at the required acceptance ratio need to be installed on both sides of the second cryomodule. With this choice, we give PERLE the future opportunity to test a cryomodule hosting additional energy-saving technologies currently under development, once they reach the required maturity.

References:

D. Angal-Kalinin et al., "Perle : Powerful Energy Recovery Linac For Experiments", Conceptual Design Report. J. Phys. G45 (6):065003, 2018.

W. Kaabi et al., “PERLE: A High-Power Energy Recovery Facility”, in Proc. 10th Int. Particle Accelerator Conf. (IPAC’19), Melbourne, Australia, May 2019, paper TUPGW008